A356 Aluminum Casting is a versatile and widely-used manufacturing process that has applications ranging from everyday cookware to cutting-edge spacecraft. This remarkable material, known for its lightweight and excellent thermal conductivity, has revolutionized various industries, offering strength, durability, and design flexibility. In this blog, we will explore the fascinating world of aluminum casting, its diverse applications, and the pivotal role it plays in shaping our modern world.

The Basics of Aluminum Casting

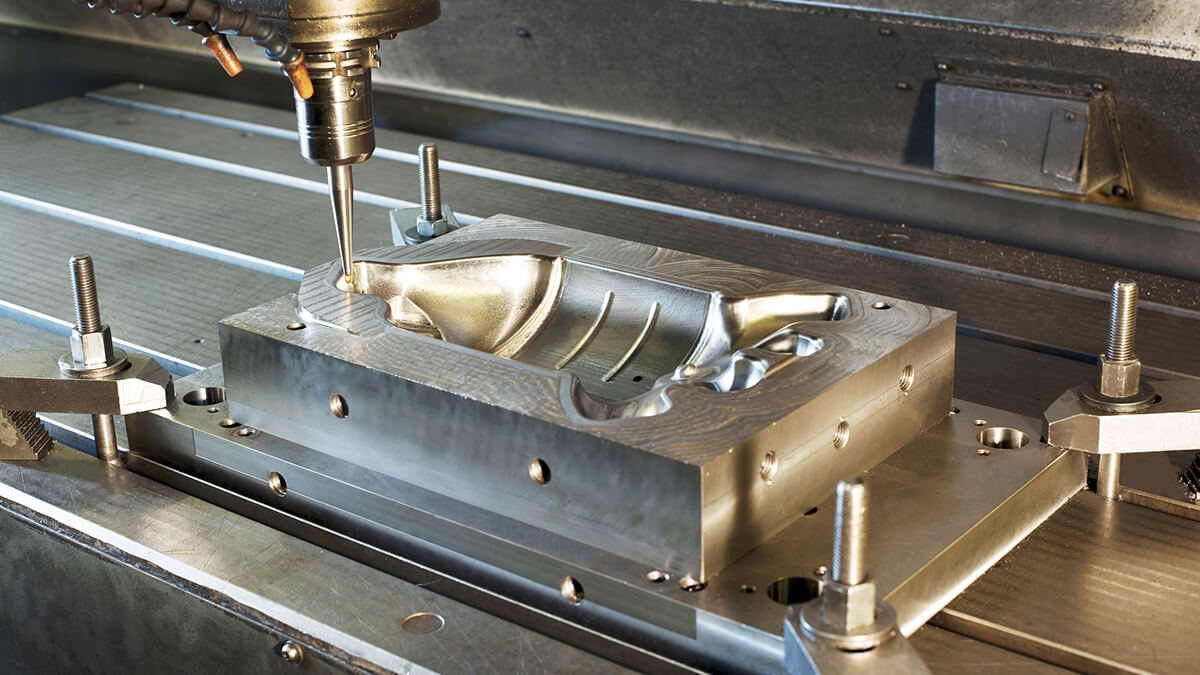

Aluminum casting is a manufacturing process that involves melting aluminum and pouring it into a mold to create a desired shape. This process can be divided into two main methods: die casting and sand casting.

- Die Casting: Die casting is a precise method used to produce complex and highly detailed parts. It involves forcing molten aluminum into a mold cavity under high pressure. This results in accurately replicated parts with tight tolerances, making it ideal for applications such as automobile components, electronic enclosures, and household appliances.

- Sand Casting: Sand casting is a more traditional and cost-effective method, often used for larger, less intricate parts. It involves creating a mold by compacting sand around a pattern (the desired shape) and then pouring molten aluminum into the mold. Sand casting is widely used in industries such as construction, aviation, and agriculture.

Cookware and Household Items

One of the most common applications of aluminum casting is in the production of cookware and household items. The excellent heat conductivity of aluminum allows for even heating, making it perfect for pots, pans, and baking sheets. Aluminum cookware is lightweight, easy to clean, and resistant to rust and corrosion. Its affordability also makes it a popular choice for kitchen utensils, such as mixing bowls and coffee makers.

Automotive and Transportation

The automotive industry relies heavily on aluminum casting for various components, including engine blocks, cylinder heads, and transmission housings. Aluminum’s lightweight properties contribute to fuel efficiency, which is crucial for modern vehicles striving to meet stringent environmental standards. Furthermore, the excellent thermal conductivity of aluminum helps dissipate heat from the engine, improving overall performance and longevity.

Aerospace and Spacecraft

Aluminum’s lightweight strength and resistance to extreme temperatures make it an essential material in aerospace and spacecraft construction. Components like aircraft wings, fuselages, and rocket parts are often cast from aluminum alloys. This allows for the reduction of weight without compromising structural integrity, which is critical for achieving escape velocity and maneuverability in space.

Electronics and Electrical Components

The electronics industry benefits from aluminum casting as well. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for housing electronic components like laptops, smartphones, and power inverters. Its high thermal conductivity also aids in dissipating heat generated by electronic devices, preventing overheating and ensuring optimal performance.

Construction and Architecture

In the construction and architecture sectors, aluminum casting is used for various applications, including door frames, window frames, and structural components. Aluminum’s resistance to corrosion and low maintenance requirements make it an excellent choice for building materials, especially in coastal areas where exposure to saltwater can be a concern.

Conclusion

From cookware to spacecraft, the versatility of aluminum casting has left an indelible mark on numerous industries. Its lightweight yet robust properties, combined with excellent thermal conductivity and corrosion resistance, have made it an indispensable material in the modern world. Whether you’re cooking a meal, driving a car, or contemplating the mysteries of the cosmos, chances are that aluminum casting has played a pivotal role in shaping your experience. As technology continues to advance, we can expect aluminum casting to remain a cornerstone of innovation and progress.